News

Global Industrial Robot Market Reaches Record $16.7 Billion

Author: Renata Poreda

January 14 2026

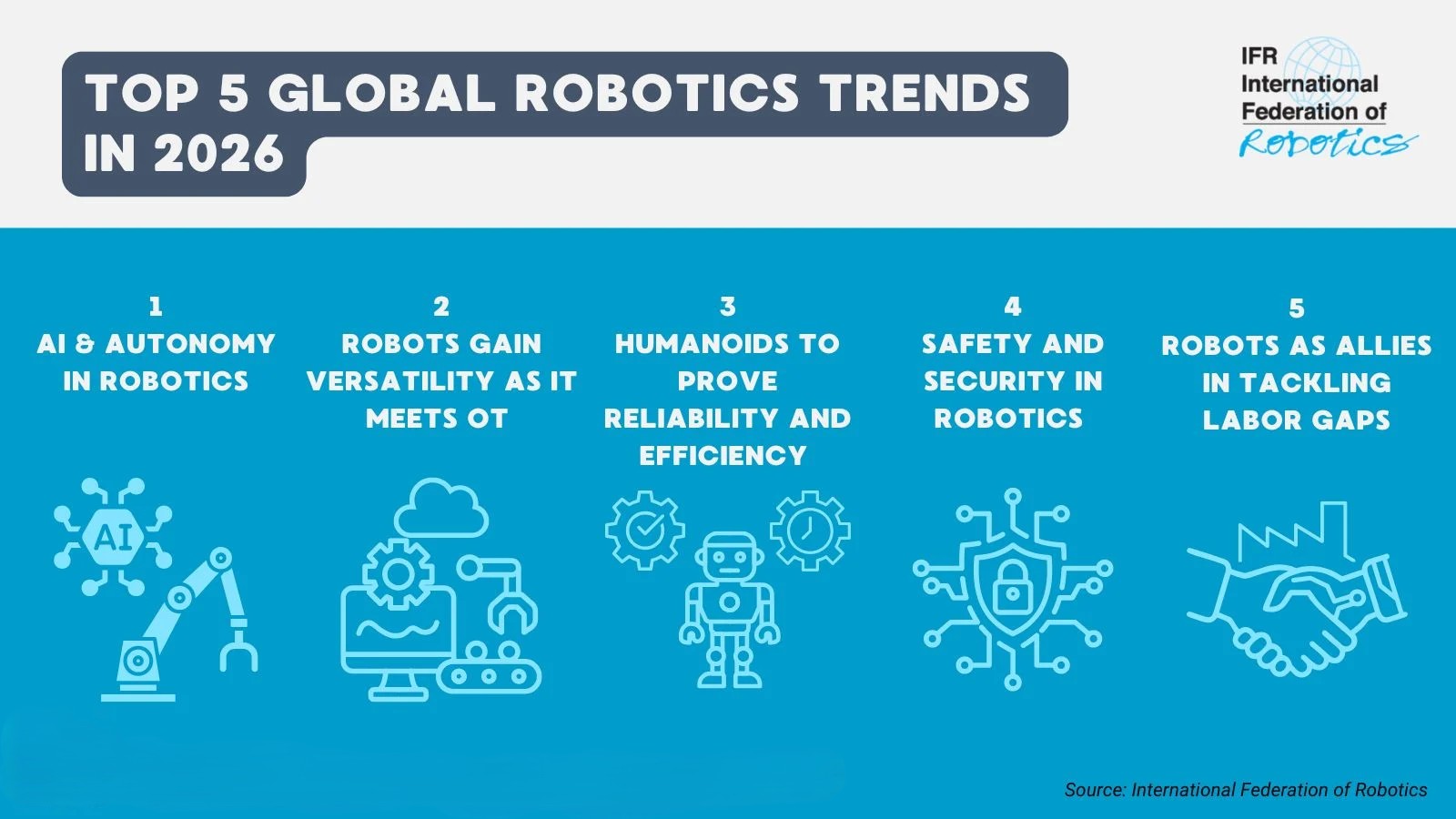

The global market value for industrial robot installations has reached a record $16.7 billion. According to the latest report from the International Federation of Robotics (IFR), industry growth in 2026 will center around five key trends dominated by Artificial Intelligence (AI), increasing robot autonomy, IT/OT convergence, and the response to global labor shortages.

The IFR report indicates that robotic systems utilizing analytical, generative, and agentic AI are playing an increasingly vital role. These systems enable autonomous decision-making, predictive maintenance, and new forms of human-robot collaboration. Simultaneously, the integration of the digital and physical worlds is growing in importance, enhancing the flexibility and versatility of robots in modern industrial plants.

A significant trend is the rapid development of humanoid robots, which are increasingly moving from pilot phases to real-world industrial deployments. Key factors for their widespread adoption include reliability, safety, and cost-effectiveness, allowing them to compete with traditional automation.

At the same time, the IFR highlights growing challenges in functional safety and cybersecurity. Integrating robots with the cloud and utilizing AI algorithms requires clear regulatory frameworks, compliance with ISO standards, and effective protection of data and production systems.

The IFR report confirms that AI and autonomy are becoming the foundation of modern robotics. For Polish industry, this is an opportunity to increase competitiveness, production flexibility, and mitigate the effects of labor shortages. Responsible implementation of these technologies—taking into account safety, workforce skills, and stable regulatory frameworks will be crucial, comments Tomasz Haiduk, President of the Polish Automation and Robotics Association (FAIRP).

Experts emphasize that robotics and automation will increasingly support workers by taking over routine tasks and enabling the development of new competencies. Companies and public administrations are intensifying reskilling and upskilling efforts to adapt the labor market to the realities of an automation-driven economy.

Five Key Trends Shaping the Robotics Industry in 2026:

1. Artificial Intelligence and autonomy in robotics

AI-powered robots capable of independent action are becoming more common. The primary benefit of AI implementation is increased autonomy, driven by three types of AI:

- Analytical AI: Enables the processing of large datasets, pattern detection, and the generation of actionable recommendations. This allows robots to predict failures in smart factories and optimize route planning and resource allocation in logistics.

- Generative AI (GenAI): Marks a shift from rule-based automation to intelligent, self-learning systems. GenAI allows robots to learn new tasks independently and generate training data in simulation environments. It also opens new forms of human-robot interaction based on natural language and image analysis.

- Agentic AI: A key direction for autonomy that combines analytical AI (structured decision-making) with generative AI (adaptability). This hybrid approach aims to enable robots to work effectively in complex, real-world environments.

2. Greater versatility through IT and OT integration

The demand for versatile robots reflects the ongoing convergence of Information Technology (IT) and Operational Technology (OT). Combining IT’s data processing power with OT’s physical control capabilities increases robot flexibility through real-time data exchange, automation, and advanced analytics. This integration is the foundation of Industry 4.0, eliminating silos between the digital and physical worlds.

3. Humanoid Robots – time for reliability and efficiency

Humanoid robots are evolving rapidly. In industrial applications, they are seen as promising solutions wherever high flexibility is required, especially in environments designed for humans. Following pioneer deployments in the automotive industry, applications in logistics and manufacturing are gaining traction. To compete with traditional automation, humanoids must meet high standards for cycle times, energy consumption, and maintenance costs.

4. Safety and cybersecurity in robotics

As robots work more closely with humans, safety is the top priority. AI-based autonomy increases the complexity of testing and validation, making human oversight essential. Systems must be certified according to ISO standards with clear liability frameworks. Furthermore, cloud-connected systems face cyber threats, and concerns exist regarding sensitive data (video, audio, sensors) collected by robots. The “black box” nature of deep learning models further drives the need for clear legal and ethical frameworks.

5. Robots as allies against aabor shortages

Employers worldwide are facing a lack of skilled workers. Implementing robotics and automation is a key strategy to counter this. Success depends on worker engagement; close collaboration during implementation increases acceptance in both the industrial and service sectors. By taking over routine tasks and opening new career paths, robots are increasingly viewed as workplace allies, while also making the industry more attractive to younger generations.